Hinkley Point C – Big Carl

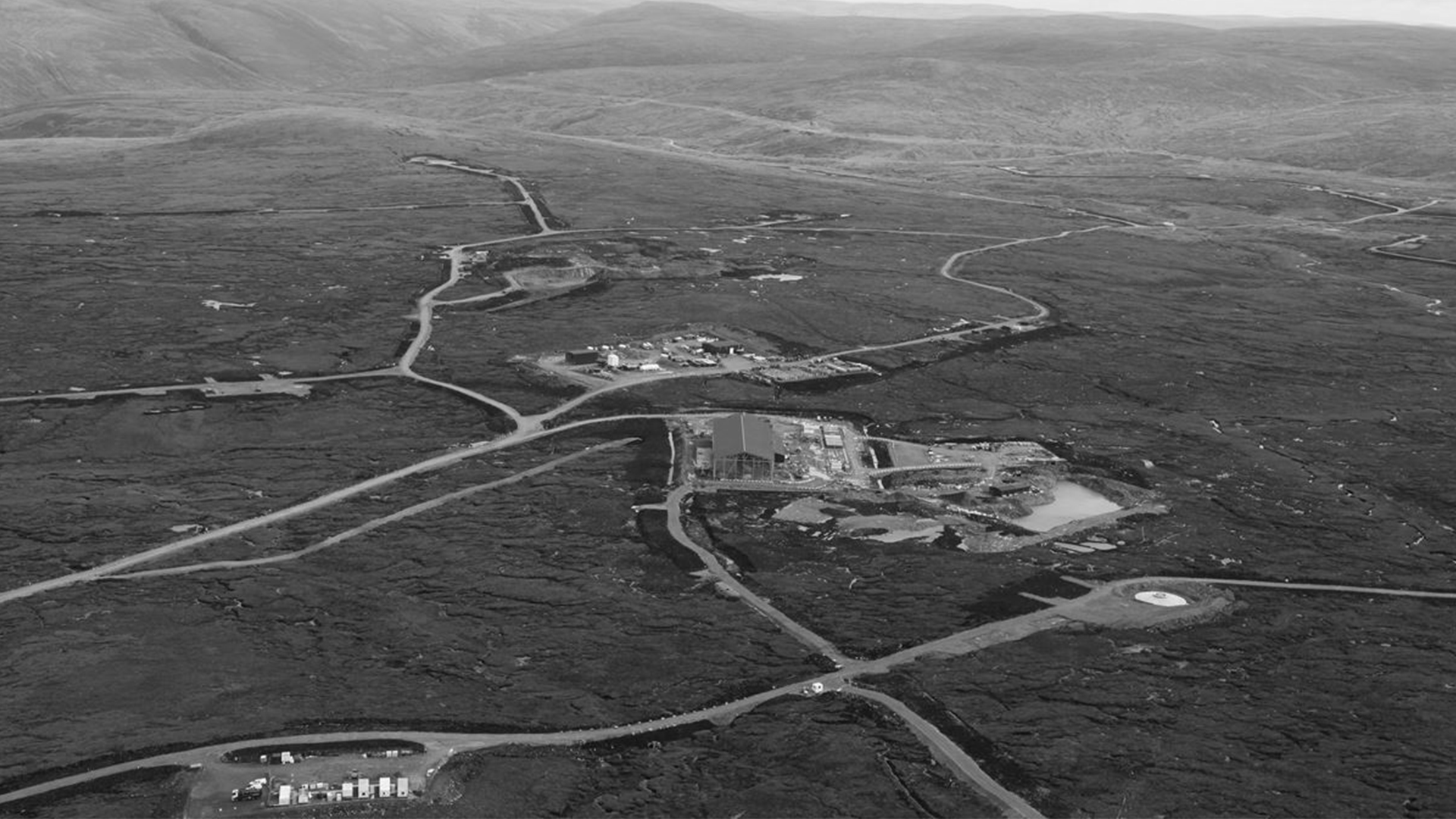

Somerset, UK

Project synopsis

Designer for temporary crane foundations and pumping stations, adapted processes to meet BYLOR standards

Contractor

BYLOR (Bouygues TP & Laing O’Rourke)

End client

EDF Energy PLC

“Big Carl” is the biggest, land-based crane in the world, specially built to reduce the construction programme on this complex site.

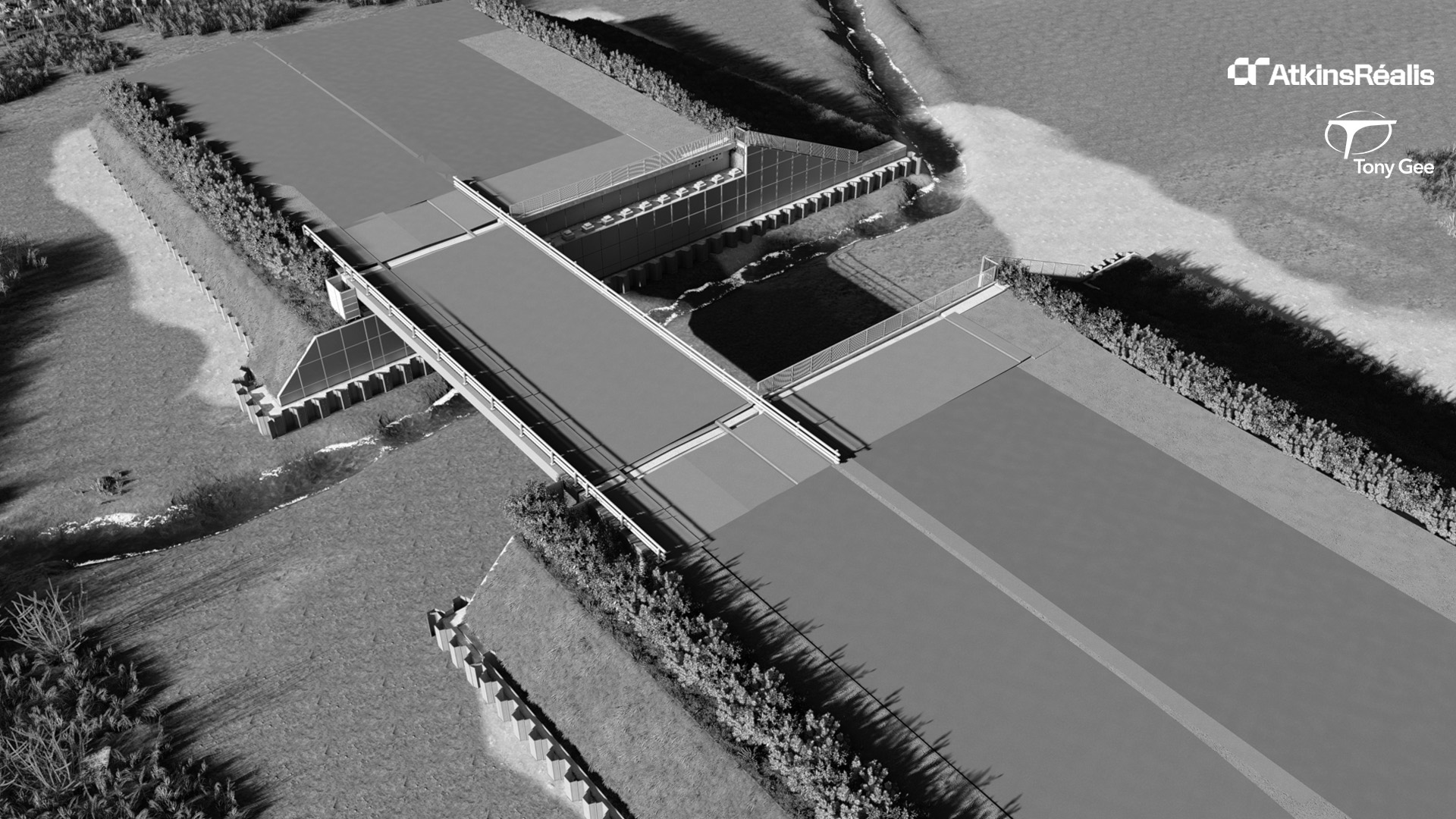

Tony Gee designed the reinforced concrete foundation using Design for Manufacture and Assembly (DfMA) to support its 500m long tracks and three, 36m diameter slew rings. We also designed the cages to be lifted, including reviewing the lifting beams, the reinforcement ties and specifying additional clamps where necessary. We responded quickly to client requests and designed a bespoke shear connection to join elements of the concrete foundation together whilst minimising changes to the reinforcement cages.

We adapted our processes to meet BYLOR (a Bouyges TP and Laing O’Rourke JV) specific modelling procedures, working with the DfMA developers and 3D reinforcement detailing software.

We designed two concrete pumping stations, utilising an existing retaining wall to minimise new foundations, and two tunnels crossing under the crane foundations, to allow concrete pumping pipes to pass under the crane. The design includes two reinforced concrete pool bunkers, with sufficient x-ray protection to contain the radiation from construction testing and required rapid collaboration with the client and other parties to solve problems as they arose, and adjusted our designs as required.

Recommended Reading